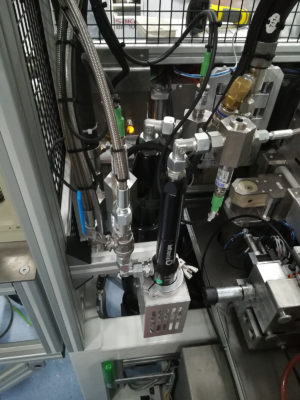

With this process, we coat sensitive components (electronic, etc.) with bi-component polymer to protect them from their external environment.

This is a complex process, which requires the part to be pre-heated beforehand, in order to optimise the quality of the polymerisation of the bi-component.

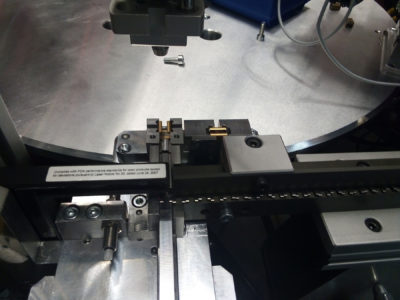

If the project requires the integration of several successive functions with a fast process cycle time, we design turntable transfers between the different stations.

A turntable is a circular table, driven by a motorised cam indexer. Equipment such as this can be used to assemble spring-loaded electrical terminals.

This realization shows the assembly of an electronic board with an integrated connector, on a case.

This process is called pressfit. It consists of exerting a controlled force in order to fit a PCB (XXX) onto fixed pins, which are themselves integrated into a housing, or onto another PCB. In this way, the electrical connection between the two components is made without soldering.

The function of this station is to join two components by riveting. The components are automatically supplied by two vibrating bowls. The first component is placed by a Scara robot, and the second is inserted by a pneumatic manipulator.

To rivet the components, we have integrated an electric press with force measurement with a maximum capacity of 5 KN; for the transfer from station to station, we have designed an electromechanical turntable system.

This robotic cell is used to handle blank electronic circuits, to engrave a serial number on them, to program them and to test their correct operation before packaging them in their transport blister pack.

We have integrated a 6-axis robot into this equipment, which handles the components, as well as a fibre laser marking system.

This equipment allows the quality of the moulded tracks of a box to be tested. To do this, we have developed a bed of nails system, which is automatically plugged into the product connector, as well as the tracks of the box.

Thus, a test bay integrating measuring instruments is controlled by a specifically developed computer program.

This system measures the electrical continuity and sends a sanction when the product does not comply with the specifications. The product is then removed from the production line.

We have also integrated a serial number control and laser marking function on the processed products, in order to guarantee the traceability of these products throughout their production process.